Kakati liquid ring vacuum pumps

are used in the Power industry for the following applications:

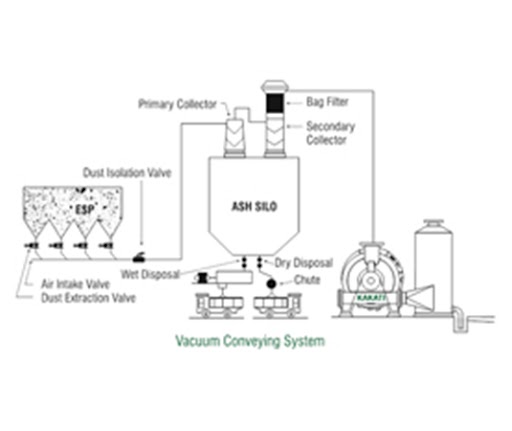

Fly Ash handling :

This involves conveying fly ash from the precipitator hoppers to a central dry collectiom point under vacuum. A barrage of pumps work synchronously to evacuate the ash from the hoppers. A good vacuum system effectively reduces your carbon foot print.

- Over 3000 installations world wide

- Available in Cast iron, stainless steel and other materials of construction

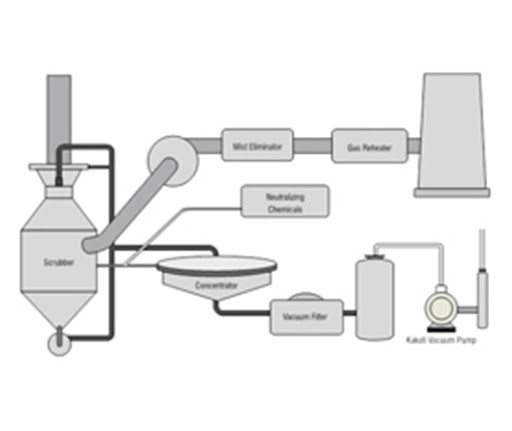

Flue gas desulfurization :

Kakati vacuum pumps are connected to vacuum filters effectively removing sulphur compounds from the aqueous slurry. A thoroughly designed pump can improve your process efficiencies and improve rate of separation.

- Over 500 installations in filtration applications worldwide

- Available in Cast iron, stainless steel and other materials of construction

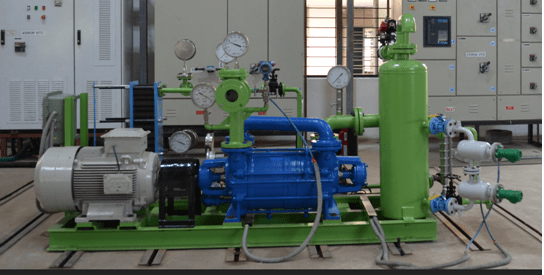

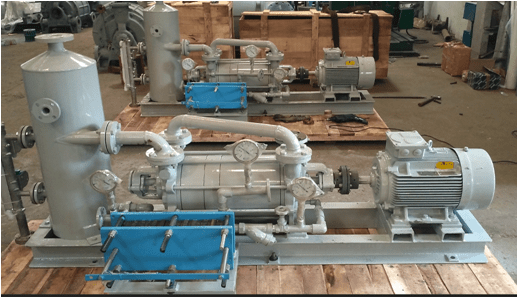

Condenser Exhauster systems:

Kakati condenser systems are self-contained and effectively remove air leakages and extra dissolved air from condensers. This improves the turbine output by lowering turbine back pressure thereby improving heat rates and reducing production costs. The package comes Skid mounted with the pump, heat exchanger Separators and associated controls. These Exhausters are industry work horses and are built for a lifetime.

Kakati manufactures upto 40scfm capacity pumps according to HEI standards in both two stage pumps and air- ejector designs. Higher size exhausters can be designed upon request.

The company has been awarded

ISO 9001Certification in the year 2005.